NEWTOP-228W

آلات تصنيع أوعية ورقية أفقية عالية السرعة

معلومات المنتج

معلمات الآلة

معلومات المنتج

السلوك الميكانيكي

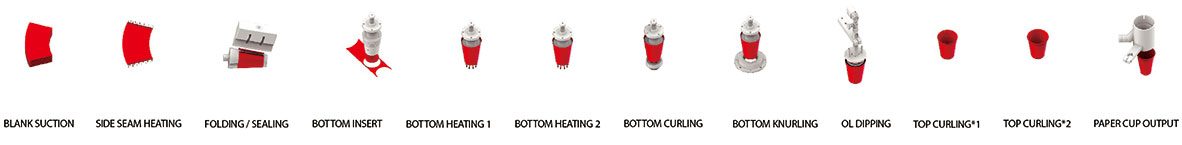

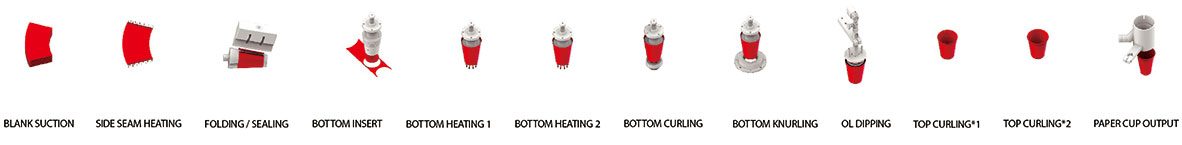

تتميز ماكينة تشكيل الأكواب الورقية الذكية عالية السرعة NEWTOP-1250S بتصميمها المكتبي الذي يفصل أجزاء التشكيل عن أجزاء النقل. جميع أجزاء النقل مثبتة في الإطار الرئيسي أسفل الطاولة، وتستخدم عمودًا طوليًا، وكامة فهرسة أسطوانية، ونظام تروس، مع تزييت بحمام زيت. أما أجزاء التشكيل، فهي مثبتة على الطاولة، مما يسهل الوصول إليها للتنظيف والصيانة. يتم التحكم بالماكينة بواسطة وحدة تحكم منطقية قابلة للبرمجة (PLC)، وتُراقب العملية برمتها بواسطة مستشعرات كهروضوئية، ويتم التغذية بواسطة محرك سيرفو. يتوفر نظام فحص بصري كخيار إضافي للتخلص من الأكواب غير المطابقة للمواصفات. هذه الماكينة مناسبة لصنع أكواب باردة/ساخنة بسعة 12-45 أونصة.

معلمات الآلة

| نموذج | NEWTOP-228W |

| الوزن | 7500 kg |

| بعد غطاء الآلة | 3300 x 2140 x 2250mm |

| الطاقة المقدرة | Three-phase, 380V, 65KW |

| الهواء المضغوط | 0.5-0.7 MPa, 0.6 m³/min |

| أقصى قدرة | 180 pcs/min |

| المواد الورقية | PE واحد / مزدوج PE / PLA |

| سمك الورق | 0.295-0.47mm |

| مجموعة المنتجات | (D1) φ100-150mm (H)50-110mm (D2) φ80-120mm (h)5-12mm |

![]() ضمان الجودة الميكانيكية

ضمان الجودة الميكانيكية

1. الأجزاء الميكانيكية مضمونة لمدة 3 سنوات، والأجزاء الكهربائية والأجزاء المعرضة للتلف مضمونة لمدة سنة واحدة.

2. جميع الأجزاء الموجودة على طاولة التشكيل يسهل الوصول إليها لأغراض الصيانة.

3. جميع الأجزاء الموجودة أسفل طاولة التشكيل مُشحّمة بحمام زيت. يجب تغيير الزيت كل 4-6 أشهر باستخدام الزيت المُحدد.

![]() كفاءة الإنتاج

كفاءة الإنتاج

1. إنتاج يصل إلى 81600 كوب لكل وردية (8 ساعات)، وما يصل إلى 6.2 مليون كوب شهريًا (3 ورديات).

2. نسبة النجاح أعلى من 99% في ظل الإنتاج العادي.

3. يمكن لمشغل واحد التعامل مع عدة آلات في نفس الوقت.

![]() ضمان جودة المورد

ضمان جودة المورد

ورقة كأس آلة

ورقة كأس آلة ورقة وعاء آلة

ورقة وعاء آلة كم آلة

كم آلة على شكل وعاء

على شكل وعاء المعدات المساعدة

المعدات المساعدة تابعنا

تابعنا